- Home Page

- Company Profile

-

Our Products

- Thread Rolling Machines

- Automatic Tapping Machine

- Bolt Former

- Nut Former

- Threading Machines

- Circular Saw

- Concentricity Gauge

- Bank Inlet Auto Lathe

- Header

- Heat Treatment Furnaces

- Nylon Nut Assembly Machine

- Oil Recycling Machine

- Hot & Cold Forging Press

- Self Drilling Screw Machine

- Die & Punches

- Friction Welding Machine

- Wire Drawing Machines

- Optical Sorting Machine

- Open Die Re Header

- Screw Point Cutting Machine

- Die Locking Machine

- Contact Us

Die Locking Machine

20000.00 - 50000.00 USD ($)/Set

Product Details:

- Control System PLC Controlled

- Model No DL-300

- Lubricating System Automatic Lubrication

- Motor Power 7.5 kW

- Frame Type Heavy Duty Welded Frame

- Cooling System Water Cooling

- Operating Temperature 5C - 45C

- Click to View more

X

Die Locking Machine Price And Quantity

- 20000.00 - 50000.00 USD ($)/Set

- 1 Set

- 25 MPa

- 20-30 seconds

- 12 Units/Hour (avg)

- 85% RH

- Low Maintenance, Easy Service Access

- 150 liters

- Emergency Stop, Interlock Guard

- 230 mm

- Touch Panel

- 980 mm

- Axial Piston Pump

- 360 mm

- Up to 300 ton

- Floor Mounted

- 120 mm/sec

Die Locking Machine Product Specifications

- DL-300

- PLC Controlled

- Heavy Duty Welded Frame

- 7.5 kW

- Mould die fitting, metal molding, industrial production

- Automatic Lubrication

- Hydraulic

- Water Cooling

- Automatic

- 5-15 kW

- Energy Efficient, Robust Construction, Easy Installation

- 0.05 mm

- <75 dB

- Die Locking Press

- 5C - 45C

- 2100 x 800 x 1800 mm

- Hydraulic

- 15 HP

- 50 Hz

- 380 V

- Up to 50 cycles/hour

- 30-300 Ton (adjustable range)

- HMI Display, USB Data Port

- Electric

- 1200 kg

- Blue & White

- Powder Coated

- Die Locking Machine

- 25 MPa

- 20-30 seconds

- 12 Units/Hour (avg)

- 85% RH

- Low Maintenance, Easy Service Access

- 150 liters

- Emergency Stop, Interlock Guard

- 230 mm

- Touch Panel

- 980 mm

- Axial Piston Pump

- 360 mm

- Up to 300 ton

- Floor Mounted

- 120 mm/sec

Die Locking Machine Trade Information

- 1000 Set Per Month

- 15 Days

Product Description

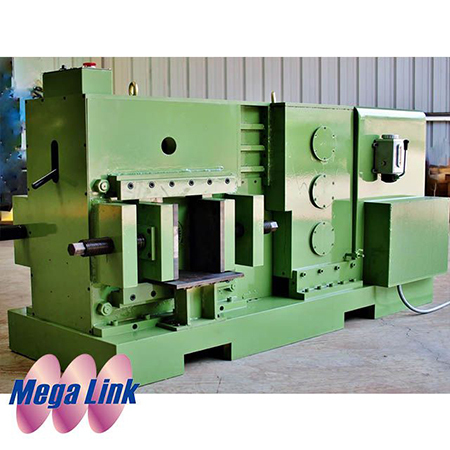

We are trading in an extensive assortment of Die Locking Machines. They are made with the assistance and dedication of our workforce and are widely utilized in several industries for carrying out die casting processes. The industrial quality norms are strictly followed at all levels of production to assure that these machines work in the most effective and efficient manner. The Die Locking Machines have a hard bitten structure, industrial tensile strength, tendency to bear extreme mechanical pressure and impact resistance.Precision and Strength for Industrial Molding

The DL-300 Die Locking Press combines substantial clamping force, reliable hydraulic technology, and precise control for die and mold fitting. Advanced features like automatic lubrication, water cooling, and integrated safety systems make it ideal for demanding metal molding applications. Its sturdy blue-and-white frame is engineered for stability and longevity in production environments.

Efficient Operation with User-Friendly Interface

Equipped with a PLC-controlled, touch-panel operator interface, the DL-300 ensures ease of use and seamless configuration. Cycle times between 2030 seconds and a working speed of 120 mm/sec optimize throughput while automated lubrication and accessible service points further reduce downtime. Its HMI display and USB port enable quick data management and system monitoring.

Designed for Safety, Durability, and Scalability

Safety is a priority, with emergency stop, interlock guard, and robust construction forming the backbone of operator protection. The DL-300 supports high-capacity cycles, energy-efficient operation, and a low-noise outputall within a heavy-duty welded frame thats easy to install and maintain. This machine meets the needs of exporters, manufacturers, and suppliers alike.

FAQs of Die Locking Machine:

Q: How does the DL-300 Die Locking Machine improve the mold fitting process?

A: The DL-300 streamlines mold fitting by offering automatic, PLC-controlled precision with up to 300 tons of adjustable clamping force and 0.05 mm accuracy. Its fast cycle times and robust safety features enhance productivity while minimizing operator intervention and risk.Q: What are the main benefits of using the DL-300 for industrial production?

A: The DL-300 delivers high efficiency, energy savings, reduced maintenance, and reliable performance. Its quick cycle time (2030 seconds) and 50 cycles/hour capacity increase throughput, while user-friendly controls and safety systems ensure smooth and secure operation.Q: When should the hydraulic oil be checked or replaced in the DL-300?

A: Hydraulic oil levels should be monitored regularly and replaced based on the manufacturers maintenance schedule or when performance drops. The 150-liter oil capacity and easy service access simplify routine checks and timely oil changes.Q: Where can the DL-300 Die Locking Machine be installed?

A: This machine is designed for floor-mounted installation in industrial settings, such as molding shops, production facilities, or manufacturing plants, where reliable die locking and molding are required.Q: What safety features are included in the DL-300 Die Locking Machine?

A: Safety measures include an emergency stop button, interlock guard system, low-noise output (<75 dB), and robust welded construction to protect operators during all automatic and manual operations.Q: How energy-efficient is the DL-300 during operation?

A: The DL-300 is engineered for energy efficiency, consuming an average of 12 units of power per hour with motor power ranging from 515 kW. Its hydraulic drive and automatic systems contribute to optimized energy usage and consistent output.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email