- Home Page

- Company Profile

-

Our Products

- Thread Rolling Machines

- Automatic Tapping Machine

- Bolt Former

- Nut Former

- Threading Machines

- Circular Saw

- Concentricity Gauge

- Bank Inlet Auto Lathe

- Header

- Heat Treatment Furnaces

- Nylon Nut Assembly Machine

- Oil Recycling Machine

- Hot & Cold Forging Press

- Self Drilling Screw Machine

- Die & Punches

- Friction Welding Machine

- Wire Drawing Machines

- Optical Sorting Machine

- Open Die Re Header

- Screw Point Cutting Machine

- Die Locking Machine

- Contact Us

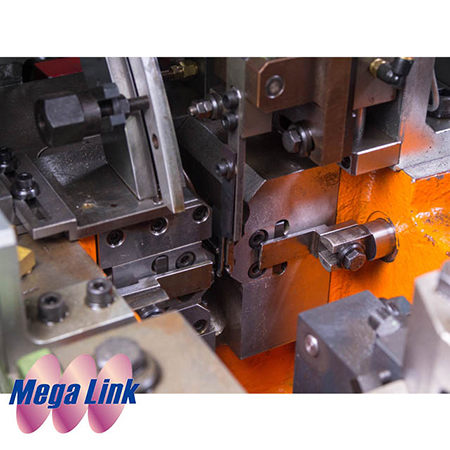

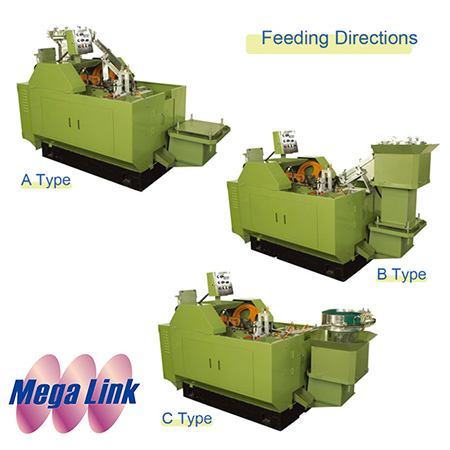

Open Die Re-Header

30000 - 60000 USD ($)/Set

Product Details:

- Type Open Die Re-Header

- Material High-grade Alloy Steel

- Application Forging and metal forming industries

- Click to View more

X

Open Die Re-Header Price And Quantity

- 30000 - 60000 USD ($)/Set

- 1 Set

- Custom shapes available

- High precision maintained

- Customizable as per requirements

- Open Die Forging

- Up to 45 HRC

- Smooth, Rust Resistant

- Normalized, Tempered

Open Die Re-Header Product Specifications

- Forging and metal forming industries

- High-grade Alloy Steel

- Open Die Re-Header

- Custom shapes available

- High precision maintained

- Customizable as per requirements

- Open Die Forging

- Up to 45 HRC

- Smooth, Rust Resistant

- Normalized, Tempered

Open Die Re-Header Trade Information

- 1000 Set Per Month

- 15 Days

Product Description

We are counted amongst as the foremost manufacturers, exporters and suppliers of Open Re-Header Machine. The offered machine is extensively used in various industries for making components, especially autoparts. The provided machine is manufactured under the vigilance of our adept technocrats using high quality components and pioneering techniques. To ensure its high durability, offered Open Re-Header Machine is checked on various parameters.

Features:

- High operational fluency

- Compact design

- Energy efficient

- Ease in installation

| Model | ML/ODH 5X75 | ML/ODH 6X160 | ML/ODH 8X200 | ML/ODH 10X300 | ML/ODH 16X400 |

| Forging Load (kgs) | 20000 | 25000 | 35000 | 40000 | 60000 |

| Max. Wire Diameter | 3~5 | 4~6 | 6~8 | 6~10 | 8~16 |

| Max. Blank Length | 25~75 | 25~200 | 25~250 | 25~350 | 25~400 |

| Punch Hole dia. (mm) | 31x75mm | 38x120mm | 42x120mm | 54x170mm | 74x200mm |

| Machine Output | 50~90 | 30~55 | 20~50 | 15~35 | 15~25 |

| Feeding Mechanism | Feeding Vibrator | ||||

| Auto Feeding Length | 25~75 | 25~150 | 25~150 | 25~200 | 25~200 |

| Main Drive Motor | 3HP | 5HP | 7.5HP | 25HP | 40HP |

| Machine Dimension | 1700x1050x1000 | 2600x1330x1800 | 3200x1510x1800 | 4450x1780x2000 | 6000x2480x3550 |

| Machine Weight | 2100 | 4000 | 6800 | 15000 | 33000 |

Engineered for Custom Performance

Each Open Die Re-Header can be tailored to meet specific weight capacities and unique shape requirements, ensuring optimal compatibility for your application. Precision engineering coupled with advanced open die forging methods enables us to deliver highly reliable products to the forging and metal forming industries worldwide.

Durability Through Advanced Treatment

Applying normalized and tempered heat treatment, our re-headers achieve a hardness of up to 45 HRC for superior longevity and resistance to wear. The smooth, rust-resistant surface finish further protects your investment, minimizing maintenance needs and downtimes in even the most demanding operations.

FAQs of Open Die Re-Header:

Q: How is high precision maintained during the production of Open Die Re-Headers?

A: High precision is ensured through advanced open die forging processes and meticulous quality control measures. This allows for tight tolerance levels, guaranteeing consistent performance and compatibility with various industrial applications.Q: What type of materials are used in manufacturing the Open Die Re-Header?

A: Each re-header is manufactured from high-grade alloy steel, selected for its strength, toughness, and ability to withstand repeated forging and metal forming stresses.Q: When is the Open Die Re-Header suitable for use in a manufacturing process?

A: The re-header is ideal for use whenever forging or metal forming operations demand versatile tools with high strength, resistance to rust, and the ability to be precision-customized according to specific shapes and weight requirements.Q: Where can these Open Die Re-Headers be supplied from?

A: Our Open Die Re-Headers are produced and exported from Taiwan, serving as a trusted supplier and manufacturer to global forging and metal forming industries.Q: What is the process involved in creating an Open Die Re-Header?

A: The re-header is produced using an open die forging process, involving the shaping of alloy steel under precise conditions, followed by normalization and tempering heat treatments, resulting in a product that is both tough and dimensionally accurate.Q: How should the Open Die Re-Header be used for best results?

A: For optimal performance, integrate the re-header within your forging or metal forming operations as specified, making sure to select a design matching your desired shape and weight capacity. Proper use ensures longevity and reliable forming results.Q: What are the key benefits of choosing this Open Die Re-Header?

A: Key benefits include robust customization options, high durability from advanced heat treatments, rust-resistant smooth surface finishes, and the ability to maintain high precision tolerances, making it a dependable solution for demanding industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email