- Home Page

- Company Profile

-

Our Products

- Thread Rolling Machines

- Automatic Tapping Machine

- Bolt Former

- Nut Former

- Threading Machines

- Circular Saw

- Concentricity Gauge

- Bank Inlet Auto Lathe

- Header

- Heat Treatment Furnaces

- Nylon Nut Assembly Machine

- Oil Recycling Machine

- Hot & Cold Forging Press

- Self Drilling Screw Machine

- Die & Punches

- Friction Welding Machine

- Wire Drawing Machines

- Optical Sorting Machine

- Open Die Re Header

- Screw Point Cutting Machine

- Die Locking Machine

- Contact Us

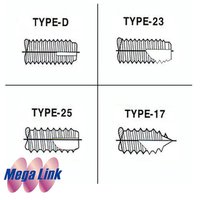

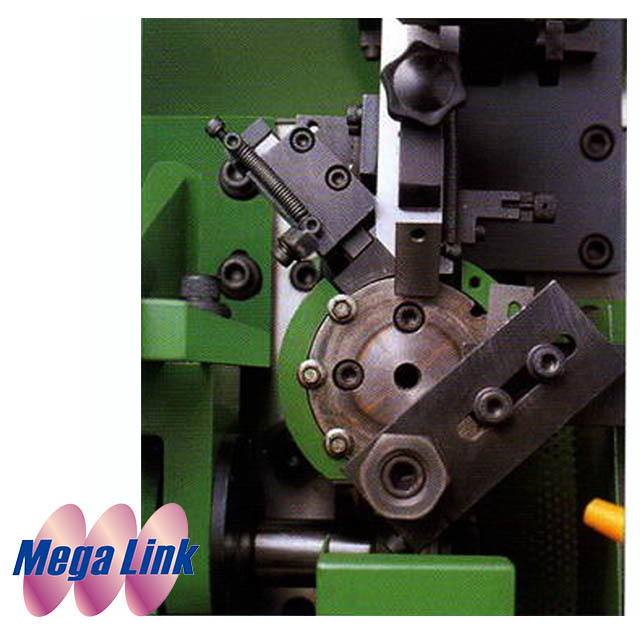

Screw Point Cutting Machine

30000 - 60000 USD ($)/Set

Product Details:

- Drive Motor Induction Motor

- Product Type Metal Cutting Machine

- General Use For Cutting Screw Points

- Material Mild Steel / Alloy Steel

- Type Screw Point Cutting Machine

- Capacity 5000-6000 pieces per shift

- Weight (kg) Approx. 350 kg

- Click to View more

X

Screw Point Cutting Machine Price And Quantity

- 30000 - 60000 USD ($)/Set

- 1 Set

- 1.2 kW

- Floor Mounted

- On-site Service Available

- Anti-corrosive Coating

- 3 mm - 10 mm

- High-Speed Steel (HSS)

- Painted/Polished

- Automatic Grease/Oil System

- Foot Pedal / Hand Lever

- <75 dB

Screw Point Cutting Machine Product Specifications

- 1 mm - 6 mm (depending on material)

- 1200 x 850 x 1300 mm

- Approx. 350 kg

- Steel, Stainless Steel, Mild Steel

- 0.05 mm

- High Precision, Rugged Design, Low Maintenance

- Mild Steel / Alloy Steel

- Water Cooled / Air Cooled

- For Screw Point Formation

- For Cutting Screw Points

- 5000-6000 pieces per shift

- Induction Motor

- Mechanical

- Adjustable as per requirement

- Up to 80 pcs/min

- Metal Cutting Machine

- Shearing/Chopping Action

- Screw Point Cutting Machine

- 220-240 V

- Semi-Automatic

- Manual Lever/Mechanical

- Blue

- 1.5 HP Electric Motor

- No

- 1.2 kW

- Floor Mounted

- On-site Service Available

- Anti-corrosive Coating

- 3 mm - 10 mm

- High-Speed Steel (HSS)

- Painted/Polished

- Automatic Grease/Oil System

- Foot Pedal / Hand Lever

- <75 dB

Screw Point Cutting Machine Trade Information

- 1000 Set Per Month

- 15 Days

Product Description

Our offered vast range of Screw Point Cutting Machines are gaining immense appreciation in the domestic as well as foreign markets for their effective and efficient performing ability. The machines are used for accurately and precisely cutting of screw threads with the aid of linear motion of the tool. The Screw Point Cutting Machines are used in different industrial sectors for completing various processes in an optimum manner. They can be availed by clients at an industry leading price.Precision Engineering for High Output

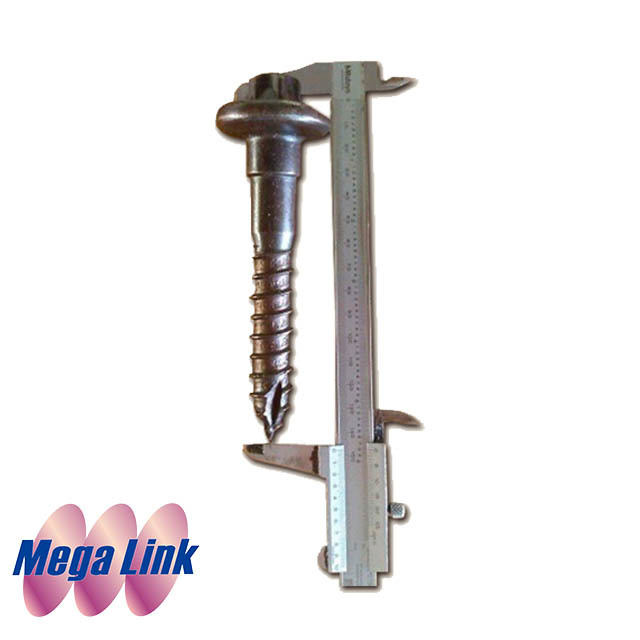

Designed for manufacturers needing accurate and efficient screw point formation, this machine achieves mechanical precision within 0.05 mm. The High-Speed Steel (HSS) blade provides a sharp, reliable cut, while the robust mechanical drive ensures consistent performance even during high-output cycles.

Rugged Construction and Low Maintenance

Built with mild steel and alloy steel, this floor-mounted unit features an anti-corrosive finish and is painted or polished for durability. Its automatic grease/oil lubrication and efficient cooling system minimize maintenance needs, allowing operators to focus on productivity rather than frequent upkeep.

User-Friendly, Flexible Operation

Switch easily between foot pedal and hand lever operation, supported by a straightforward, manual control system. With adjustable cutting thickness and area, it is simple to customize output for varying screw sizes. The machine is semi-automatic and does not require advanced computer skills for effective use.

FAQs of Screw Point Cutting Machine:

Q: How does the Screw Point Cutting Machine ensure precise screw point formation?

A: The machine utilizes a mechanical drive system with high-precision shearing or chopping action. Its HSS blade and robust construction enable accuracy within 0.05 mm, ensuring consistently formed screw points for various material types.Q: What materials and diameters can be processed with this machine?

A: The Screw Point Cutting Machine is suitable for processing steel, stainless steel, and mild steel within an input diameter range of 3 mm to 10 mm. The adjustable cutting area enables versatility across different screw specifications.Q: Where can this machine be installed, and what are the installation requirements?

A: This unit is designed to be floor-mounted. It requires a stable installation space (dimensions: 1200 x 850 x 1300 mm) and a standard 220-240V electrical connection. It is suitable for industrial environments including manufacturing workshops and screw production facilities.Q: What is the operational process for cutting screw points?

A: Operators can use either a foot pedal or hand lever to activate the machine, which then shears or chops the input material using an HSS blade. Automatic lubrication and cooling systems keep the device running smoothly throughout high-volume production shifts.Q: When is maintenance required on this machine?

A: Thanks to its automatic lubrication and durable build, the machine requires minimal regular maintenance. Routine checks on the lubrication and cooling systems as well as periodic blade inspection help ensure long-term reliability.Q: What are the key benefits of using this screw point cutting machine?

A: Benefits include high-precision cutting, rugged and durable design, fast production speeds up to 80 pcs/min, and low operational noise below 75 dB. The semi-automatic function and easy controls minimize operator fatigue and boost efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email